LEGGER AND ENGLISH FOOTER

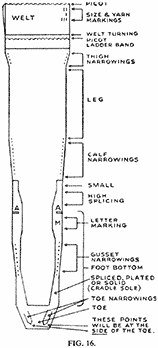

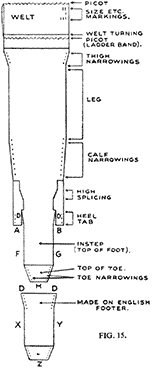

1. The leg, heel-tabs, instep and the top of the toe portion of the stocking are made in one piece on a machine called a 'Legger.'

2. The heel-tabs are looped together on a Linking (Looping) machine so that “A” is joined to “B”.

3. The selvedge of the heel-tabs which was adjacent to the instep is then “waled” or “rubbed-out” with a hand tool to make a slack wale along the inside of the heel. This slack wale is run-on to the points of a bar called the transfer bar. The points of this bar are grooved so that they may fit over the needles of an English Footing machine and so facilitate the transference of the heels to the needles of the Footer.

4. The foot bottom (commencing from the heel selvedges) is knitted so that its shape corresponds to that of the instep and top of the toe.

5. The toe end of the leg “H” is linked to the toe end of the sole “Z”.

6. Selvedges “F” and “X” are seamed, as also are the selvedges “G” and “Y”, forming joins along each side of the foot.

7. The leg is then seamed, forming a join at the back of the leg.