17

DYEING AND FINISHES

WHY NYLON IS PRE-BOARDED

In the discovery of nylon, the Chemical Industry has proved its ability to create its own raw material, this material having characteristics not possessed by any fibre, and because of these, any desired pre-set shape can be put into nylon stockings while in the Grey (Greige—U.S.A.) this process being known as “pre-boarding” (or the thermal setting of the hose by steam above atmospheric pressure for a pre-determined period). The hose is submitted to this moulding process prior to being dyed.This pre-boarding produces shrinkage of the yarn fabric, and the hosiery is, therefore, made extra long in the leg and foot to allow for this.

Pre-boarding should not be confused with “the final boarding stage”—see “Eye-Catching Finish” page 118. It is an operation comprising the putting of the stockings on to shapes following the contour of the leg, after which, a number of the hose are placed in a container and exposed to steam for a period of, usually, two to five minutes. This hot, wet treatment is the aftermath of manufacture, and it is desirable for nylon stockings in the unfinished state to be pre-boarded within a reasonable time (this process determining the permanent shape of the hose) and it has been found in actual practice that if the process of pre-boarding is left too long, creases will develop, some of which are very difficult to eradicate, while others—according to the period left—are permanent. This is one reason why the necessity for pre-boarding is, therefore, obvious. The result of pre-boarding nylon hosiery is that the stockings retain their shapeliness through long wear and repeated washings.

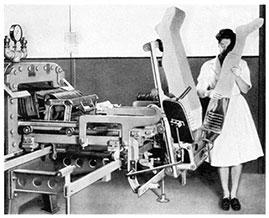

An appliance used for this “setting” effect is known as the Pegg-Paramold Pre-Boarding machine. Fig. 53 shows this machine, which has a rectangular steam chamber (or retort). This unit is closed except for a small self-sealing door at the front, which is held closed by the steam, pressure within during operation. The steam chamber accommodates 24 hosiery forms, or shapes, per set, and the machine