Foot. The nylon/acetate process gives approx. 7% greater stretch.

Welt. The nylon/acetate process gives approx. 14% greater stretch.

Owing to the larger loop formation and the resultant mechanical stretch and elastic recovery of the fabric (enabling the hose to return to its original size after stretch) this is then able to accommodate an infinite variety of wearers of whatever leg contour.

HOW A COURSE OF KNITTED LOOPS IS MADE ON THE FULLY-FASHIONED MACHINE

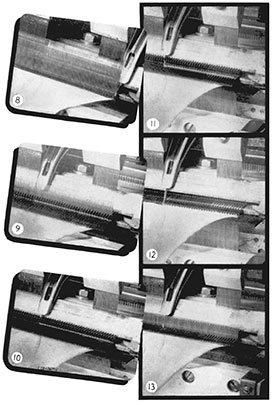

(See Fig. 23. photographs marked 8 to 13,also drawings Figs. 24-29)

8. The needle stems, surrounded by the formed loops of the last knitting course, stand in between the sinkers (thin steel plates which control the lead of the thread and measure the yarn for the stocking course) and the thread carrier shown at the right of the picture is brought into action for the first movement towards the formation of a row of knitted loops to make the next knitting course. This is called “Laying the thread”.

9. As the thread carrier moves across the knitting needle-bar width, the sinkers advance gradually, one by one, and in so doing kink the thread between alternate needle stem spaces in such a way that the loops form a corrugated course called “Sinking the loops”. The dividing sinkers now advance simultaneously, at this juncture, and the needles recede slightly to relieve the stress on the thread. As there is always a divider between each two sinkers, the yarn is now linked between every needle, the operation being referred to as “Dividing the loops”.